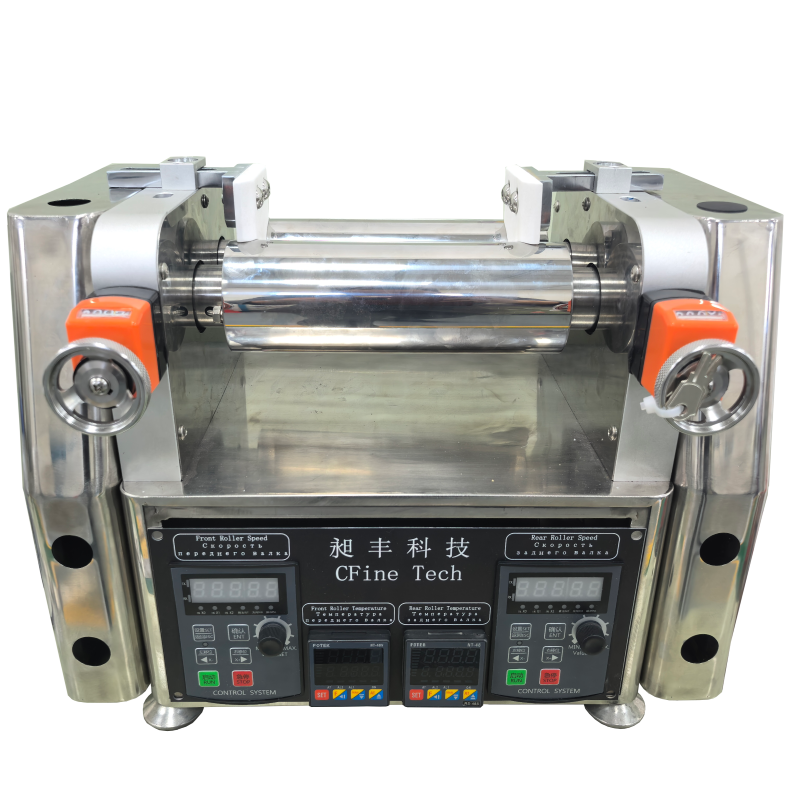

Custom 2-inch Small Lab Two Roll Mill

Uniform Mixing & Plasticizing:

Parallel rollers with adjustable gap ensure consistent blending and molten material.

Efficient Rubber Compounding:

Squeezing, shearing, and chemical reactions promote even dispersion and improved material properties.

- Overview

- Recommended Products

Custom 2-inch Small Lab Two Roll Mill

Product Introduction

An open-type plastic material intermittent mixing equipment with adjustable inter-roll gap is called an open mill. It consists of two parallel rollers.

Product Function

The main function is to mix and homogenize the raw materials, and then melt and plasticize them, providing the continuous rolling machine with uniformly mixed and plasticized molten materials.

Product Use

During the rubber compounding process, the internal mixer mainly relies on the squeezing and shearing effects produced by the two rotating rollers that are in opposite directions. Through multiple kneading and mixing processes, chemical reactions also occur during the compounding process, which break the large molecular chains inside the rubber and plastic, allowing the various components within the rubber compound to be evenly mixed and dispersed. Eventually, the goal of compounding is achieved.