Custom 6-inch Dual Inverter Open Mixing Mill For Rubber

Precise & Uniform Mixing:

Mirror-chromed rollers with adjustable gap and temperature control ensure consistent dispersion.

Safe & Durable Operation:

Equipped with multi-directional safety devices for reliable and long-lasting use.

- Overview

- Recommended Products

Custom 6-inch Dual Inverter Open Mixing Mill For Rubber

Product brief introduction

This experimental open-type mixer mill is designed for the mixing and dispersion of engineering plastics, pigment masterbatches, silicone rubber, and other polymers. It features double rollers with mirror-chromed surfaces, equipped with electric heating and water cooling systems to ensure uniform surface temperatures. The gap between the two rollers is adjustable to accommodate various processing needs. Additionally, the machine is equipped with multi-directional safety protection devices, making it safe, reliable, and durable inoperation.

Mixing Mill Technical Data

| CF-120 | CF-160 | CF-200 | CF-230 | Remarks | |

| Diameter of Barrel(mm) | 120 | 160 | 200 | 230 | Can be customized according to customer requirements |

| Length of Barrel(mm) | 350 | 350 | 520 | 620 | |

| Batch Feeding(g) | 500~800 | 800~1500 | 1500~2600 | 3000~5000 | |

| Electrical Heating(kw) | 0.75 | 1.5 | 3.75 | 3.75 | |

| Water Cooling(kw) | 3.75 | 5.5 | 7.5 | 11 | |

| Weight(KG) | 400 | 600 | 850 | 1100 |

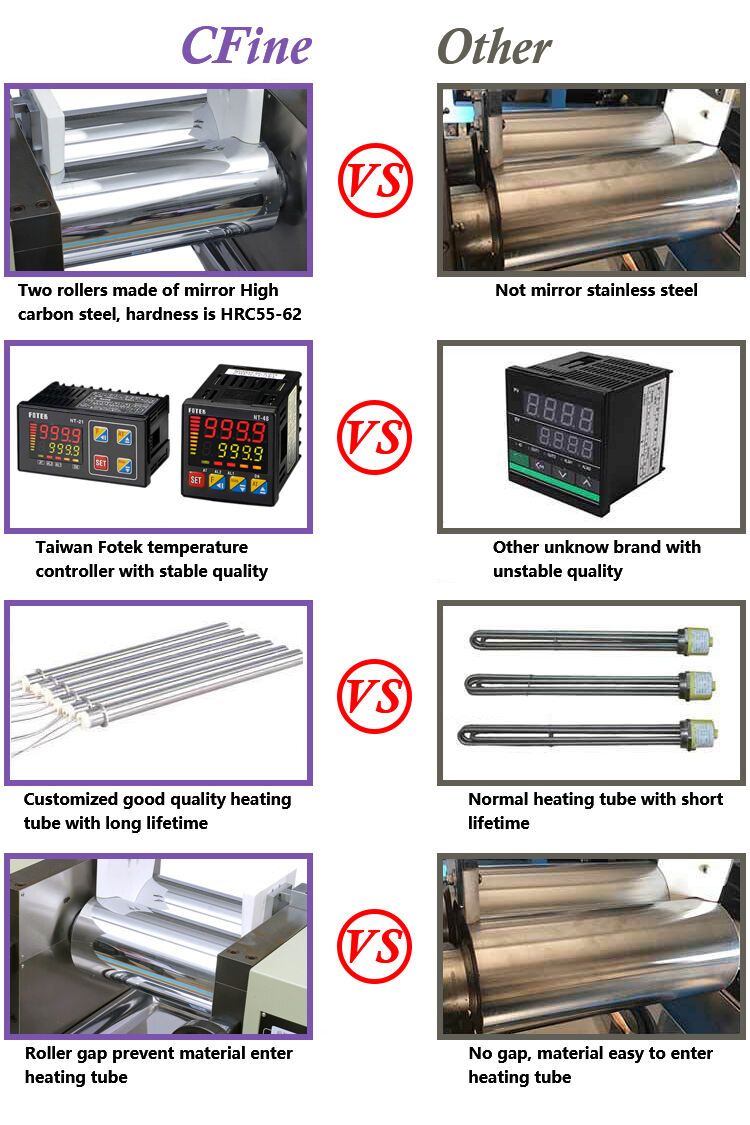

Product Superiority

1.Two rollers made of mirror high carbon steel,hardness is HRC55-62

2.Taiwan Fotek temperature controller with stable quality

3.Customized good quality heating tube with long lifetime

4.Roller gap prevent material enter heatingtube