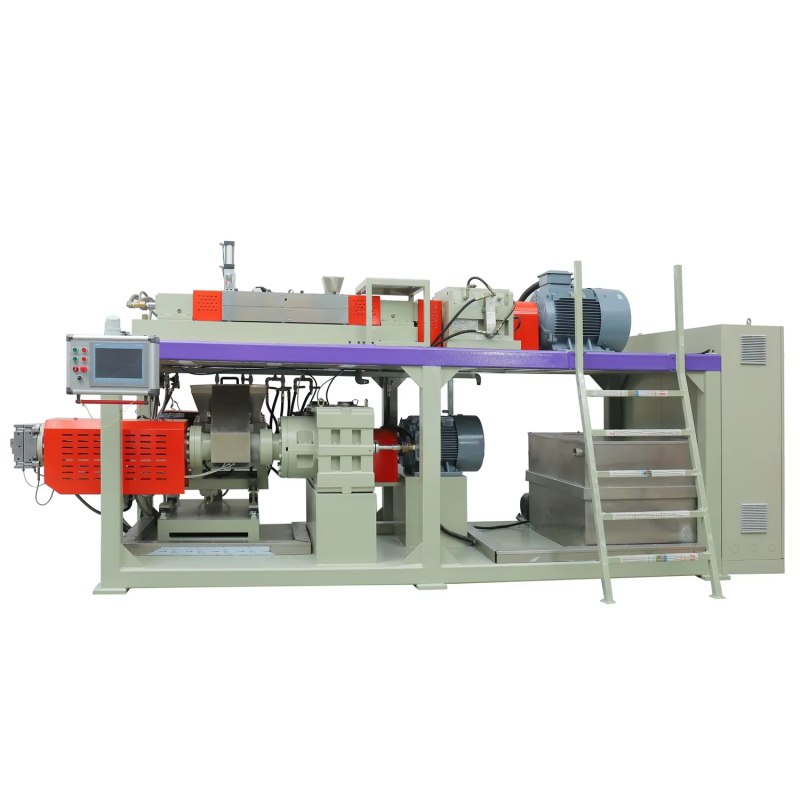

Easy Clean Double Wrist Granulator Machine Forced Air Cooling Metal Granulator

Forced Double-Wrist Feeding:

Ensures consistent material flow and reduces the need for extra crushing.

Contamination-Free Granulation:

Prevents material contamination during the granulation process.

- Overview

- Recommended Products

Custom Easy Clean Experimental Double Wrist Granulator For Metal

Product brief introduction

This granulator adopts forced double-wrist feeding to force feed the mixed metal powder agglomerate materials, which reduces the traditional process of additional crushing that affects material granulation and also prevents the contamination of materials in the crushing process.

Technical Data

| CF-45 | CF-60 | ||

| Screw Diameter | mm | 45 | 60 |

| Length Diameter Ratio | L/D | 12:1 | 12:1 |

| Main Motor Power | kw | 5.5 | 11 |

| Twin Rolls Power | kw | 0.75 | 1.5 |

| Capacity | kg/h | 15-25 | 30-60 |

Product Superiority

1.The function is the same as the production granulator,just the capacity is decreased and power consumption reduced.

2.It fits to develop new samples or new formula,save a lot cost.

3.The working process is easy and safe,and easy to clean.

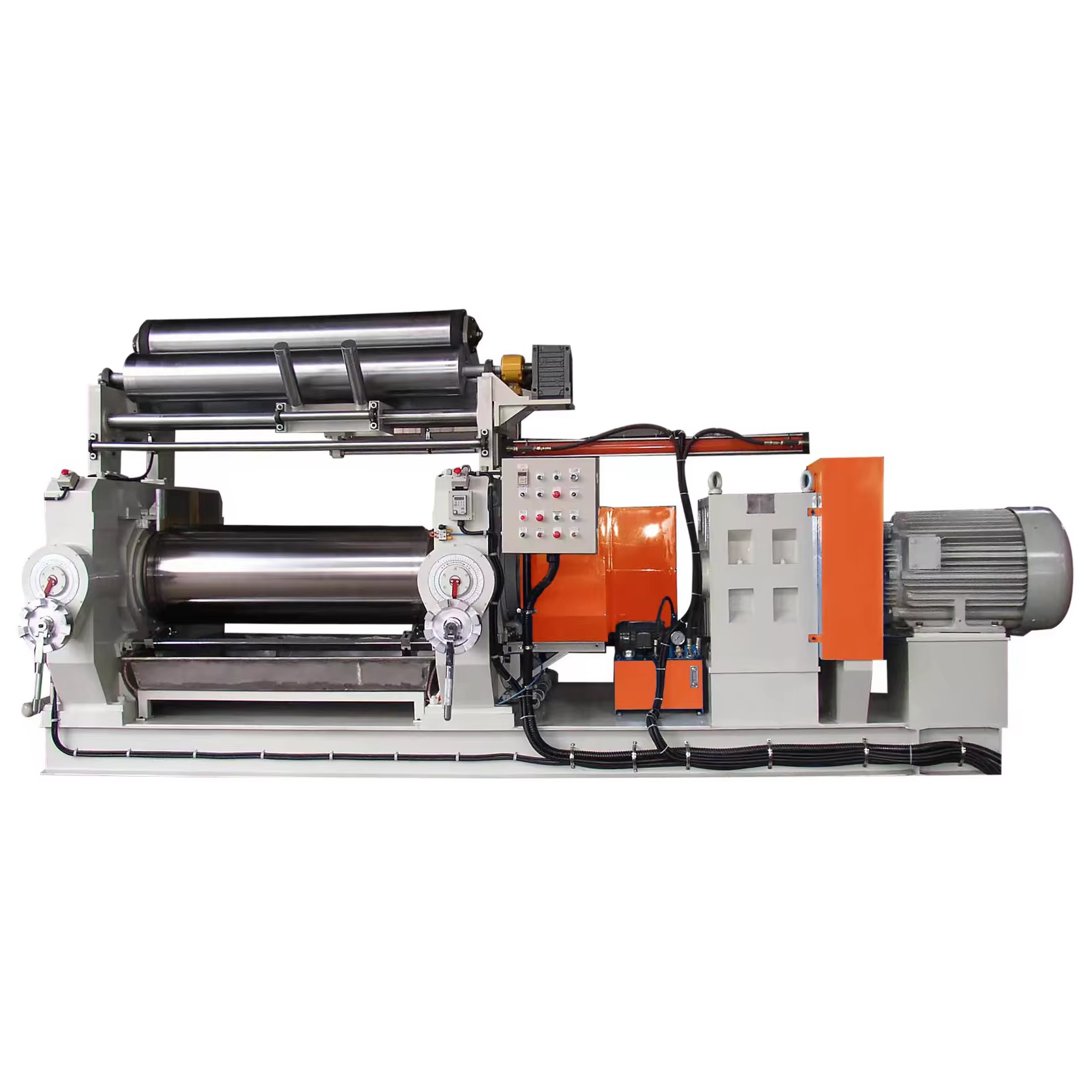

Gearbox

The product design adopts the technical specifications specified in ZBJ19009-88. The gears and shaft parts are made of high-strength alloy steel. The gear accuracy is GB10095-88, grade 6, and the tooth surface hardness is HRC-60. An oversized thrust bearing is configured at the output shaft end to bear the back thrust of the screw. The main standard parts such as bearings and oil seals are all made of domestic high-quality products. The whole machine has a high load-bearing capacity, stable transmission, low noise and high efficiency.

A. Reduction ratio: 10:1

B. Hardened tooth surface ground gears are used, low noise, long life, and reliable operation

C. Oil-immersed lubrication system

Barrel and Screw

A. Barrel and screw material: 38CrMoALA alloy steel nitrided for 72 hours, polished, surface wear-resistant treatment. (Specialized for metal powder)

B. Nitriding layer depth: 0.6-0.8mm, nitriding hardness: screw 780HV, barrel 850HV

C. Screw diameter: Ø45mm

D. Screw aspect ratio: 12:1

Electrical Control

A. Power supply: 3-AC380V, 50HZ

B. Temperature control: 3 zones, digital temperature controller

C. Electric control cabinet and host are integrated

D. Electrical control components are from Taiwan Shilin, Omron, and Tende

After-sales Service

During normal use, non-consumable parts are guaranteed for one year. We provide on-site installation guidance and long-term technical support.

Note: Electrical components and motors are imported from Taiwan and foreign brands.