Custom 30L Consumption Combined Mixer-Granulator

All-Alloy Construction:

Durable parts require no coating or plating, ensuring long service life.

Efficient Mixing & Granulation:

Provides uniform dispersion and produces paste-ready material for the next process.

- Overview

- Recommended Products

Custom 5L Low Price Consumption Combined Mixer-Granulator

Product brief introduction

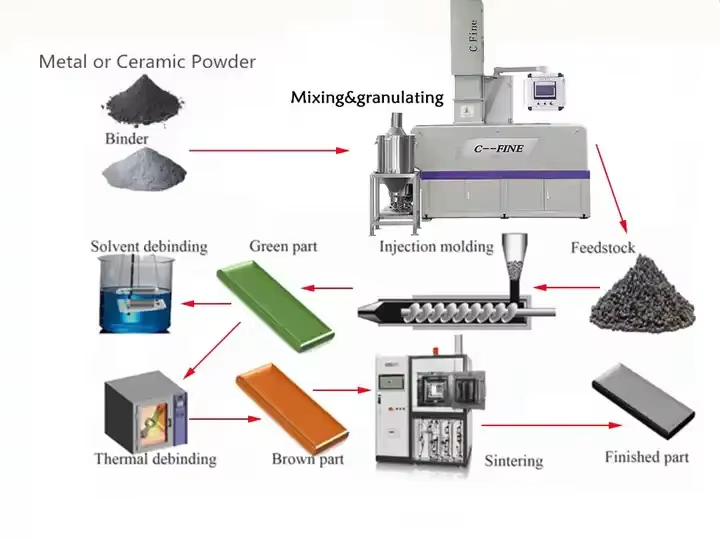

The mixer’s chamber, side plate, hammer, and blade shaft are fabricated from full-alloy materials, requiring no additional coatings or plating. It is designed for efficient mixing, dispersing, and processing of metal powders and binder formulations at specific temperatures. After the mixture reaches a paste-like state, it undergoes extrusion and granulation before entering the following step.

Technical Data

| CF-1L35Z | CF-5L60Z | CF-10L75Z | CF-15L80Z | CF-30L80Z | |

| Capacity | 1L | 5L | 10L | 15L | 30L |

| Main Motor | 3.75kw | 7.5kw | 15kw | 18.5kw | 11kw*2 |

| Pressure Cylinder | ¢63 | ¢100 | ¢160 | ¢160 | ¢250 |

| RPM (front/rear) | 0- 40/31 r/min | ||||

| Type of Cooling | Electric Heating | ||||

| Type of Heating | Ventilation cooling | Water-cooling | Ventilation cooling | ||

| Gauge of the screw rod | 35mm | 60mm | 75mm | 80mm | 85mm |

| Extrusion Motor | 2.2kw | 5.5kw | 7.5kw | ||

| Grinding Motor | 0.75kw | ||||

| Size | L1850*W1200*H2000mm | L2000*W1100*H2200mm | L2650*W1300*H2800mm | L2750*W1400*H2800mm | L3100*W1600*H2800mm |

| Weight | About 1200kg | About 2200kg | About 2800kg | About 3000kg | About 4500kg |

| Power | 3∮ AC380V 50HZ | ||||

Working Principle of Internal Mixer

Within the mixing chamber, two counter-rotating rotors grip the incoming feed and drive it into the gap, where it is subjected to powerful squeezing and shearing. The material then strikes the distinctive “W” edge, dividing into two streams that circulate around the chamber and back to the rotor top. This closed environment, controlled for both temperature and pressure, delivers intensive shear and mixing, ensuring the formulation is evenly dispersed, plasticized, and optimized for maximum performance.

Mixing System

The mixing chamber is "W" shaped, and adopts an "M" shaped lower pressure cover to form a fully enclosed mixing space. The stirring blade adopts a prismatic spiral design without dead angles, so that the material shearing and dispersion can meet the physical property requirements. The stirring blade is a hollow structure, and the part in contact with the material (mixing chamber/side plate/pressure hammer/stirring blade shaft) is made of full alloy material (no need for spraying or electroplating), which is wear-resistant, corrosion-resistant, not easy to stick to the material, and has a long service life.

Product Superiority

1. The motor and electrical components adopt a fully sealed structure, which is waterproof and dustproof.

2. The oil outlet is equipped with a pressure gauge, which automatically alarms when the pressure is too high.

3. The oil storage tank is out of oil.

4. The oil filling operation cycle-the single oil filling time can be set on the control panel.

5. A dust and odor-proof collection shield is installed above the mixing tank, with an air outlet to facilitate the connection of the factory dust collection system, effectively reducing the harm of dust and harmful gases to operators.

6. Thermal insulation system.

After-sales Service

During normal use, non-consumable parts are guaranteed for one year. We provide on-site installation guidance and long-term technical support.

Note: Electrical components and motors are imported from Taiwan and foreign brands.